Preparation of items for Autoclaving:

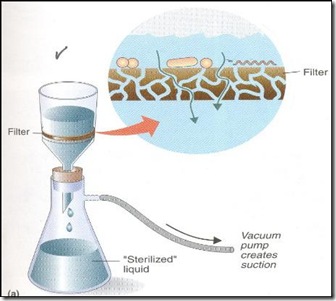

In preparing items for autoclaving, containers should be unsealed and articles should be wrapped in materials that allow steam penetration. Large packages of dressings and large flasks of media require extra time for heat to penetrate them. Likewise, packing many articles close together in an autoclave lengthens the processing time to as much as 60 minutes to ensure sterility. It is more efficient and safer to run two separate, uncrowded loads than one crowded one. Wrapping objects in aluminum foil is not recommended because it may interfere with steam penetration. Steam circulates through an autoclave from a steam outlet to an air evacuation port (figure ).

Importance:

Moist heat in the form of pressurized steam is regarded as the most dependable method for the destruction of all forms of life, including bacterial spores. This method is incorporated into a device called the autoclave. Over 100 years ago, French and German microbiologist developed the autoclave as an essential component of their laboratories.

Need of autoclaving:

Reliable sterilization with moist heat requires temperatures above that of boiling water. These high temperatures are most commonly achieved by steam under pressure in an autoclave. Autoclaving is the preferred method of sterilization, unless the material to be sterilized can be damaged by heat or moisture.

Effectiveness of Autoclave or Optimum Conditions:

Sterilization in an autoclave is most effective when the organisms are either contacted by the steam directly or are contained in a small volume of aqueous (primarily water) liquid. Under these conditions, steam at a pressure about 15 psi; attaining temperature (121oC) will kill all organisms and their endospores in about 15 minutes.

Principle of Autoclaving:

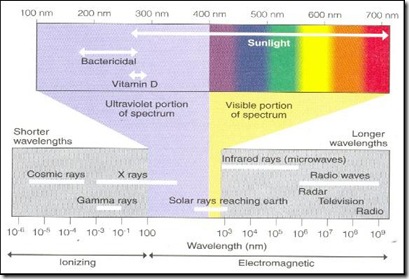

A basic principle of chemistry is that when the pressure of a gas increases, the temperature of the gas increase proportionally. For example, when free flowing steam at a temperature of 100oC is placed under a pressure of 1 atmosphere above sea level pressure – that is, about 15 pounds of pressure per square inch (Psi) --- the temperature rises to 121oC. Increasing the pressure to 20 psi raises the temperature to 126oC. The relationship between temperature and pressure is shown in table 2. In this way steam is a gas, increasing its pressure in a closed system increases its temperature. As the water molecules in steam become more energized, their penetration increases substantially. This principle is used to reduce cooking time in the home pressure cooker and to reduce sterilizing time in the autoclave. It is important to note that the sterilizing agent is the moist heat, not the pressure.

| Table | The Relationship Between the Pressure and Temperature of Steam at Sea Level* |

| Pressure (psi in excess of atmospheric pressure) | Temperature (oC) |

| 0 psi | 100 |

| 5 psi | 110 |

| 10 psi | 116 |

| 15 psi | 121 |

| 20 psi | 126 |

| 30 psi | 135 |

Rules implied for Autoclaving:

Sterilization by autoclaving is invariably successful if properly done and if two common-sense rules are followed:

First, articles should be placed in the autoclave so that steam can easily penetrate them.

Second, air should be evacuated so that the chamber fills with steam.

Working of Autoclave:

Most autoclaves contain a sterilizing chamber into which articles are place and a steam jacket where steam is maintained. As steam flows from the steam jacket into the sterilizing chamber, cool air is forced out and a special valve increases the pressure to 15 pounds/square inch above normal atmospheric pressure. The temperature rises to 121.5oC, and the superheated water molecules rapidly conduct heat into microorganisms. The time for destruction of the most resistant bacterial spore is now reduced to about 15 minutes. For denser objects, up to 30 minutes of exposure may be required. The conditions must be carefully controlled or serious problems may occur.

Uses of Autoclave:

Autoclaving is used to sterilize culture media, instruments, dressings, intravenous equipment, applicators, solutions, syringes, transfusion equipment, and numerous other items that can withstand high temperatures and pressures. The laboratory technician uses it to sterilize bacteriological media and destroy pathogenic cultures. The autoclave is equally valuable for glassware and metalware, and is among the first instruments ordered when a microbiology laboratory is established. Autoclaves are also used on large industrial scale. Large industrial autoclaves are called retorts, but the same principle applies for common household pressure cooker used in the home canning of foods

Limitations and Disadvantages of Autoclave:

The autoclave also has certain limitations. For example, some plasticware melts in the high heat, and sharp instruments often become dull. Moreover, many chemicals breakdown during the sterilization process and oily substances cannot be treated because they do not mix with water.

Heat requires extra time to reach the center of solid materials, such as caned meats, because such materials do not develop the efficient heat-distributing convection currents that occur in liquids. Heating large containers also requires extra time. Table 3 shows the different time requirements for sterilizing liquids in various container sizes. Unlike sterilizing aqueous solutions, sterilizing the surface of a solid requires that steam actually contact it.

| Table 3 | The effect of Container Size on Autoclve Sterilization Times for Liquid Solutions* |

| Container Size | Liquid Volume | Sterilization Time (min) |

| Test Tube: 18×150 mm | 10 ml | 15 |

| Erlenmeyer Flask: 125 ml | 95 ml | 15 |

| Erlenmeyer Flask: 2000 ml | 1500 ml | 30 |

| Fermentation Bottle: 9000 ml | 6750 ml | 70 |

Indicator of Sterilization Achievement:

Several commercially available methods can indicate whether sterilization has been achieved by heat treatment. Modern autoclaves have devices to maintain proper pressure and record internal temperature during operations. Regardless of the presence of such a device, the operator should check pressure periodically and maintain the appropriate pressure. Chemical reactions in which an indicator changes color when the proper times and temperatures have been reached. In some designs, the word "sterile" or "autoclaved" appears on wrappings or tapes. These tapes are not fully reliable because they do not indicate how long appropriate conditions were maintained. Tapes or other sterilization indicators should be placed inside and near the center of large packages of determine whether heat penetrated them. In another method, a pellet contained within a glass vial melts. A widely used test consists of preparations of specified species of bacterial endospores such as Bacillus stearothermophilus, impregnated into paper strips. The spore strip and an ampule of medium are enclosed in a soft plastic vial. The vial is placed in the center of the material to be sterilized and is autoclaved. After autoclaving, these can then be aseptically inoculated into culture media. Growth in the culture media indicates survival of the endospores and therefore inadequate processing. Other designs use endospore suspensions that can be released, after heating, into a surrounding culture medium within medium within the same vial.

Important Points to Remember For Autoclaving:

Steam under pressure fails to sterilize when the air is not completely exhausted. This can happen with the premature closing of autoclave's automatic ejector valve. The principles of heat sterilization have a direct bearing on home canning. To sterilize dry glassware, bandages, and the like, care must be taken to ensure that steam contacts all surfaces. For example, aluminum foil is impervious to steam and should not be used to wrap dry materials that are to be sterilized; paper should be used instead. Care should also be taken to avoid trapping air In the bottom of a dry container because trapped air will not be replaced by steam, which is lighter than air. The trapped air is the equivalent of a small hot-air oven, which, as we will see shortly, requires a higher temperature and longer time to sterilize materials. Containers that can trap air

should be placed in a tipped position so that the steam will force out the air. Products that do not permit penetration by moisture, such as mineral oil or petroleum jelly, are not sterilized by the same methods that would sterilize aqueous solutions. This precaution is necessary because when an object is exposed to heat, its surface becomes hot much more quickly than its center. (When a large piece of meat is roasted, for example, the surface can be well done while the center remains rare.)

Prevacuum Autoclave:

In large laboratories and hospitals, where great quantities of materials must be sterilized, special autoclaves, called prevacuum autoclaves, are often used. This machine draws air out of the sterilizing chamber at the beginning of the cycle. Saturated steam is then used at a temperature of 132oC to 134oC at a pressure of 28 to 30 lb/in2. The time for sterilization is now reduced to as little as 4 minutes. A vacuum pump operates at the end of the cycle to remove the steam and dry the load. The major advantages of the prevacuum autoclave are the minimal exposure time for sterilization, the reduced time to complete the cycle and the costs of sterilization are greatly decreased.